What are Shelters and Hardened Facilities?

Shelters and hardened facilities are specially designed safe spaces built to protect nation, equipment, and critical operations from extreme dangers like explosions, harmful chemicals, biological contaminants, and radiation. They create a secure physical barrier from the outside world during emergencies and are designed to help you survive safely and comfortably when external conditions are unsafe.

Why Do We Use Them?

Life Protection: To keep our facility safe from blasts, toxic gases, or hazardous fallout.

Equipment Safety: To shield important machines or military systems that must keep working during crises.

Continuity of Operations: To ensure vital work continues uninterrupted, whether at command centres, laboratories, or bunkers.

When are They Used?

You might depend on a shelter or hardened facility during:

- A war or explosion threat needing blast and pressure protection

- An NBC event (Nuclear, Biological, or Chemical hazard)

- An industrial accident-causing toxic gas release

How These Facilities Work – Step-by-Step

Normal Operation: Under normal conditions, the shelter quietly runs its air filtration and pressure systems in the background. These systems work together to continuously supply clean, breathable air contamination free air inside the shelter. The air filtration removes dust, pollutants, and any minor contaminants, while the pressure system keeps the indoor air at a slightly higher pressure than outside, which helps prevent any unwanted air or particles from sneaking in. This ensures that the shelter is always ready to provide a safe environment, even before any emergency occurs.

Threat Detected: When outside danger arises, specialized sensors start working—they detect harmful chemicals, dangerous biological agents, radiation, or sudden pressure changes caused by explosions. Once these sensors detect a threat, they immediately alert the Shelter Control System (SCS), which acts like the shelter’s brain. The SCS reacts fast by automatically closing the blast valves and airtight doors to seal off the shelter from dangerous outside air or blast waves, ensuring that no harmful elements can enter.

Continuous Monitoring: While the shelter is sealed, the SCS continues to keep a constant watch on many important factors: air pressure, temperature, humidity, the presence of any harmful gases or particles, and carbon dioxide (CO₂) levels. If any readings move outside of safe ranges, the SCS automatically adjusts the ventilation, filtration, and pressure systems to restore balance. This continual monitoring ensures that the shelter’s environment stays comfortable, safe, and stable—protecting the health and safety of everyone inside.

Emergency Stabilization: People inside breathe out carbon dioxide (CO₂), which can build up over time in a sealed environment. If the CO₂ level rises above safe limits, the shelter’s CO₂ removal unit activates automatically. This important system scrubs the Co2 and maintain the environmental range of co2. This function is critical for long-term stays, preventing headaches, dizziness, or more serious health effects caused by poor air quality. The environment inside remains clean, comfortable, and safe, even if the emergency outside lasts for hours or days. Throughout this time, the SCS acts as a vigilant guardian, constantly making adjustments and ensuring the shelter fulfils its promise of safety and protection.

Core Mechanical Components

| Component | Purpose |

|---|---|

| Blast Doors | Protect from external explosions and impacts |

| Airtight Doors | Completely seal the shelter, preventing contaminated air entry |

| Blast Valves | Balance internal pressure and block harmful blast waves |

Blast Doors

Blast doors are specially engineered, heavy-duty doors designed to protect the shelter and its occupants from external explosions and impacts. These doors are typically made of reinforced steel and are installed at entry points to prevent blast waves and flying debris from penetrating the shelter.

They are built to withstand extremely high-pressure levels and sudden forces generated by explosions. When a blast occurs, these doors remain sealed and structurally intact, providing a critical barrier that preserves the internal environment and safety of those inside.

Airtight Doors

Airtight doors serve the essential function of completely sealing the shelter to prevent any contaminated air or harmful gases from entering. They are constructed with tight seals and robust locking mechanisms that ensure no leaks even under pressure differences or hazardous outside conditions.

Blast Valves

Blast valves are critical protective elements installed on air intake and exhaust points of the shelter’s ventilation system. Their primary purpose is to allow normal airflow during everyday operation but to automatically close upon detecting a sudden blast wave or pressure surge from an explosion.

This prevents the destructive blast wave from entering the shelter through ventilation ducts. These valves are typically self-actuated, meaning they respond instantly and automatically without human intervention.

Together, these components—blast doors, airtight doors, and blast valves—form the physical defence system of hardened shelters, ensuring that occupants remain shielded from both physical impacts and hazardous airborne threats during emergencies.

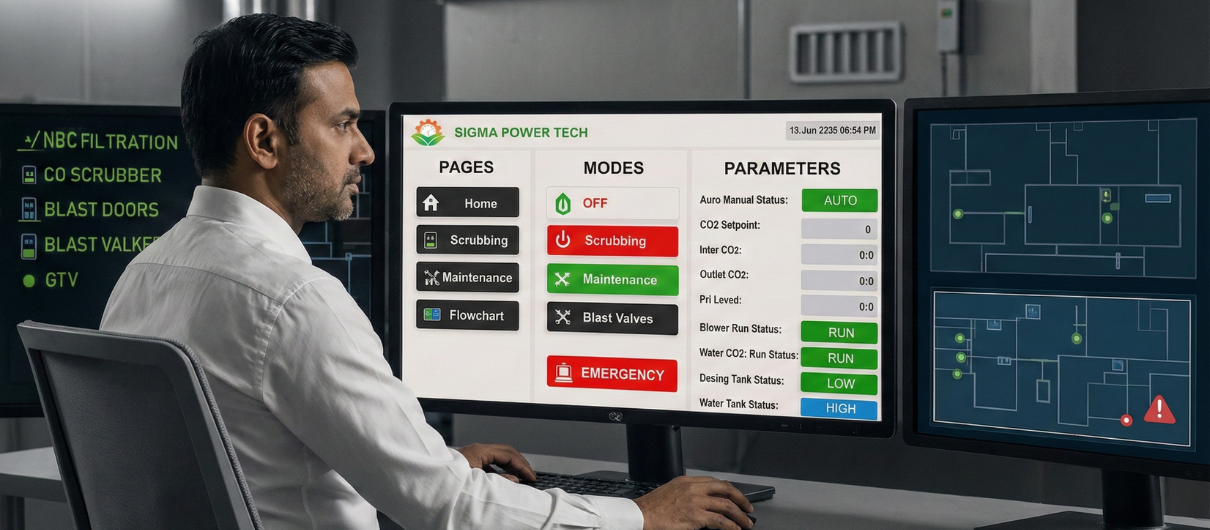

Shelter Control System (SCS)

What is SCS?

The Shelter Control System, or SCS, is the shelter’s “brain” — a highly intelligent, automated system that constantly monitors and manages all safety features inside the shelter. In an emergency, it makes decisions and takes actions faster than a person could, helping keep everyone safe without needing manual input.

Why use SCS?

A fully automated system like the Shelter Control System (SCS) eliminates the need for manual intervention, ensuring reliable operation without requiring dedicated manpower.

Ensures Safety Automatically: It guarantees safety even if people inside cannot operate the system due to stress or confusion.

Real-Time Adjustments: It controls air pressure, filtration, and alarms, adapting instantly to changing conditions.

User-Friendly Operation: Designed to run smoothly in the background, making shelter use easy and worry-free for occupants.

When and How is it used?

- The SCS operates whenever the shelter is in use, either during an emergency or regular readiness testing.

- It constantly monitors environmental risks like chemical, biological, or radiological threats.

- It maintains comfortable, safe conditions inside—such as stable air quality, temperature, and humidity—even for long stays.

Components Managed Under Shelter Control System (SCS)

NBC Detector

The NBC (Nuclear, Biological, Chemical) detector is the shelter’s early warning system. It continuously scans the outside environment and air inside the shelter for dangerous particles, chemicals, or biological agents.

Once the detector senses a threat, it instantly alerts the Shelter Control System (SCS), which then seals the shelter airtight and activates the filtration systems to purify the air. This ensures that no harmful substance enters the shelter, keeping everyone inside safe during contamination events or alerts.

Pressure Control (GTV + OPM)

Maintaining a safe indoor atmosphere is critical. The Pressure Control system uses sensors to monitor the air pressure inside the shelter, keeping it at a slightly higher level than outside. This positive pressure means that any leaks push air outwards rather than letting contaminated air in.

The SCS reads data from these sensors and adjusts valves and fans automatically to maintain this safe pressure, ensuring contaminants are kept outside at all times.

NBC Filtration

The NBC filtration system is responsible for scrubbing the air entering the shelter. It removes harmful dust, chemical gases, and biological particles from the intake air. The SCS manages the filtration modes, switching between normal and emergency operation depending on the level of external threat detected by the NBC detectors. This filtration ensures that even if the outside air is heavily contaminated, the air inside remains clean and breathable.

CO₂ Removal Unit

People inside the shelter breathe out carbon dioxide (CO₂), which can accumulate to unsafe levels over time in a sealed environment. The CO₂ removal unit scrubs and removes this excess CO₂ from the shelter air, maintaining oxygen balance essential for long-term occupancy. The SCS continuously monitors CO₂ levels and automatically activates this unit as needed to maintain a healthy indoor atmosphere.

Blast Doors

Blast doors are engineered for robust physical protection against shockwaves, overpressure, and forced entry. Inside the shelter control system, blast doors feature motorized controls and sensors that enable automated operation. SCS manages door closure in seconds during emergencies—either

through manual command or automatically via threat detection. System feedback confirms closed and locked status, maintaining airtight security.

Rapid response: Shelter control system closes blast doors instantly in crisis.

Remote monitoring: Door status, motor function, and seal integrity are tracked 24/7.

Safety integration: Emergency lock/unlock protocols prevent human error.

Blast Valves

Blast valves safeguard internal air ductwork and entries from sudden blasts or pressure spikes. Fully controlled by the shelter control system, blast valves operate instantaneously in sync with blast doors and other safety components. Their status, operational cycles, and maintenance requirements are monitored and reported for reliable performance.

Automated Closure: Shelter control system activates valves in under a second.

Duct and Inlet Protection: Ensures shelter remains uncompromised even during direct attack.

Integrated Diagnostics: SCS alerts operators of valve health and readiness.

Airtight Valves

Airtight valves are designed to ensure a complete seal in the shelter’s ventilation system, preventing contaminated air from entering. Operated automatically by the Shelter Control System (SCS), these valves open to allow fresh air during normal operation and close instantly when a threat is detected. They work closely with blast doors and blast valves to maintain a secure, positive pressure environment inside the shelter.

Continuous monitoring by the SCS ensures valve status, sealing integrity, and functionality are maintained at all times, with alerts provided for any maintenance needs. Robust construction and tight sealing materials guarantee reliable performance during emergencies.

Automatic operation: Opens and closes based on SCS commands or threat detection.

Sealing integrity: Maintains shelter airtightness by preventing air leaks.

Positive pressure support: Assists in sustaining outward airflow to block contaminants.

Real-time monitoring: Continuous status and maintenance alerts from the SCS.

Maintenance and Reliability

No shelter is effective without ongoing maintenance. Routine checks guarantee instant, reliable response when emergencies occur.

Maintenance Step-by-Step

Visual Inspection: Check door seals, filters, gauges, and mechanical parts.

Functional Test: Simulate alarm activation, verifying valves, CO₂ scrubbers, and alarms work correctly.

Pressure and Leak Tests: Perform twice yearly or after any structural modifications.

Documentation & Monitoring: Log all inspections and tests to ensure compliance and future planning.

Why Maintenance Matters

Regular maintenance is vital to keep your shelter fully operational and ready when emergencies strike. A well-maintained shelter ensures safety and builds confidence for all who rely on it. Any malfunction during a crisis could risk lives and disrupt critical functions.

Our shelters feature multiple backup systems and advanced monitoring, so if one component fails, others take over seamlessly. Routine inspections and upkeep catch problems early, preventing major failures and ensuring ongoing reliability.

By prioritizing maintenance, you safeguard your investment in safety and technology, guaranteeing your shelter performs perfectly—no matter the threat.

Hardware Supported by Our Shelter Control System

NBC Filtration Unit

The NBC filtration unit is a specialized air purification system that removes nuclear, biological, and chemical agents from incoming air, ensuring a safe environment during severe external threats. Integrated with the shelter control system, NBC filtration units operate automatically based on real-time sensor input. The system continuously monitors outdoor contamination levels and the health of filter modules (HEPA and activated carbon). SCS regulates airflow, switches filtration modes, and activates standby filter banks to maintain both overpressure and optimal air purity, without requiring manual intervention.

Automatic activation: The shelter control system immediately engages NBC filtration when threat sensors detect contamination.

Performance monitoring: Status, filter life, and flow rates are visually displayed and tracked.

Failover and redundancy: SCS controls backup filtration modules, extending safe occupancy periods.

CO₂ Removal System

Proper management of air quality is essential during extended shelter stays, where CO₂ accumulation poses health risks. The CO₂ removal system, controlled by the shelter control system, uses intelligent air quality sensors to monitor CO₂ concentration and oxygen levels. Based on these readings, SCS activates or regulates CO₂ scrubbers, automatically balancing fresh air and preventing suffocation.

Continuous Monitoring: The shelter control system analyses CO₂ and O₂ levels in real time.

Automatic Adjustment: Scrubbers and ventilation settings are managed with precision for occupant comfort and safety.

Energy Optimization: SCS reduces unnecessary system operation, optimizing power consumption.